Product Description:

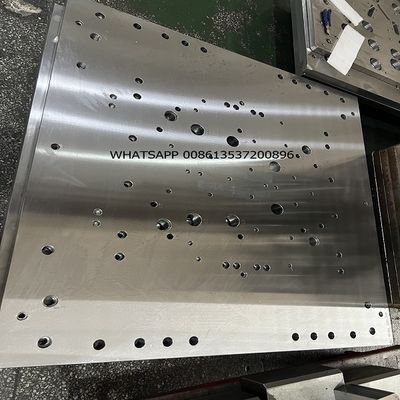

HOT WORK STEEL FOR DIE MOLD

When it comes to high-quality hot work tool steel for die mold applications, our SKD 61 Steel Round Bar stands out as a top choice. This product is specifically designed to meet the demanding requirements of die mold production, offering exceptional performance and reliability.

Service: 24 Hours Online And Free Sample

Our commitment to customer service is unparalleled, with 24-hour online support to address any inquiries or assistance you may need. Additionally, we offer free samples of our SKD 61 Steel Round Bar so you can experience its superior quality firsthand.

Quality Assurance: 100% UT D/d Passed

Rest assured, our hot work tool steel undergoes rigorous quality assurance measures to ensure top-notch performance. With a 100% Ultrasonic Testing (UT) D/d passed certification, you can trust in the reliability and durability of our SKD 61 Steel Round Bar.

Elongation: 10-15%

One of the key attributes of our hot work steel is its impressive elongation rate of 10-15%. This level of elongation allows for flexibility and resilience in the material, making it ideal for various die mold applications where durability is crucial.

Special Use: Aluminium Mold Production

Our SKD 61 Steel Round Bar is specially crafted for the production of aluminum molds, offering exceptional performance and precision in this specific application. Its unique properties make it an excellent choice for demanding aluminum mold production processes.

Melting Route: EAF, EAF+ESR, EAF+LF+VD, EAF+LF+VD+ESR

Our hot work tool steel is produced through various melting routes, including Electric Arc Furnace (EAF), EAF+ESR (Electroslag Remelting), EAF+LF+VD (Ladle Furnace + Vacuum Degassing), and EAF+LF+VD+ESR. Each melting route ensures the purity and quality of the material, meeting the highest industry standards.

Features:

- Product Name: 1.2714 HOT WORK TOOL STEEL

- Service: 24 Hours Online And Free Sample

- Melting Route: EAF, EAF+ESR, EAF+LF+VD, EAF+LF+VD+ESR

- Width: 205-610mm

- Special Use: HOT WORK STEEL FOR DIE MOLD

- Type: ESR OR EAF

Technical Parameters:

| Melting Route |

EAF, EAF+ESR, EAF+LF+VD, EAF+LF+VD+ESR |

| Elongation |

10-15% |

| Hardness |

Annealing, Can Do 58-65HRC |

| Type Of Mold |

H-Type/I-Type/T-Type |

| Type |

ESR OR EAF |

| Width |

205-610mm |

| Quality Assurance |

100% UT D/d Passed |

| Ultrasonic Test |

100% UT Passed |

| Ut Test Standard |

SEP1921-84 Class3 C/c To D/d |

| Lead Time |

20days For Custom Size |

Applications:

When it comes to high-quality hot work tool steel, look no further than the misung steel brand. The 1.2343, 1.2344, H13, SKD61 models are versatile and reliable choices for various applications. Originating from China , these steel products have undergone 100% UT (Ultrasonic Test) and have passed with flying colors.

The 1.2714 HOT WORK TOOL STEEL is designed to excel in a wide range of product application occasions and scenarios . Whether you are working on H-Type, I-Type, or T-Type molds , this steel can meet your needs effectively. With a thickness range of 20-250mm , the 1.2344 HOT WORK STEEL ROUND BAR is a reliable choice for various projects.

Manufactured according to the UT test standard SEP1921-84 Class3 C/c to D/d , these hot work tool steels offer exceptional quality and performance. Additionally, the availability of free samples makes it easier for customers to test and evaluate the product before making a purchase.

Whether you are working on hot work steel for die mold applications in the automotive, aerospace, or manufacturing industries, the misung steel products are up to the task. Their durability, strength, and versatility make them suitable for a wide range of occasions and scenarios .

Customization:

Product Customization Services for the Hot Work Tool Steel:

Brand Name: misung steel

Model Number: 1.2343 1.2344 H13 SKD61

Place of Origin: China

Melting Route: EAF, EAF+ESR, EAF+LF+VD, EAF+LF+VD+ESR

Quality Assurance: 100% UT D/d Passed

Special Use: Aluminium Mold Production

Type Of Mold: H-Type/I-Type/T-Type

Type: ESR OR EAF

Keywords: HOT WORK STEEL FOR DIE MOLD, SKD 61 STEEL ROUND BAR, HOT WORK STEEL FOR DIE MOLD

Packing and Shipping:

Product Packaging:

The Hot Work Tool Steel product is carefully packaged in sturdy boxes to ensure safe transportation and delivery. Each steel piece is securely wrapped and cushioned to prevent any damage during transit.

Shipping Information:

Orders for the Hot Work Tool Steel product are typically shipped within 1-2 business days after payment confirmation. We offer various shipping options including standard and expedited delivery to suit your needs. Tracking information will be provided once the order is dispatched.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!